The Output Map: SERVOn_FUNCTION

Executive Summary

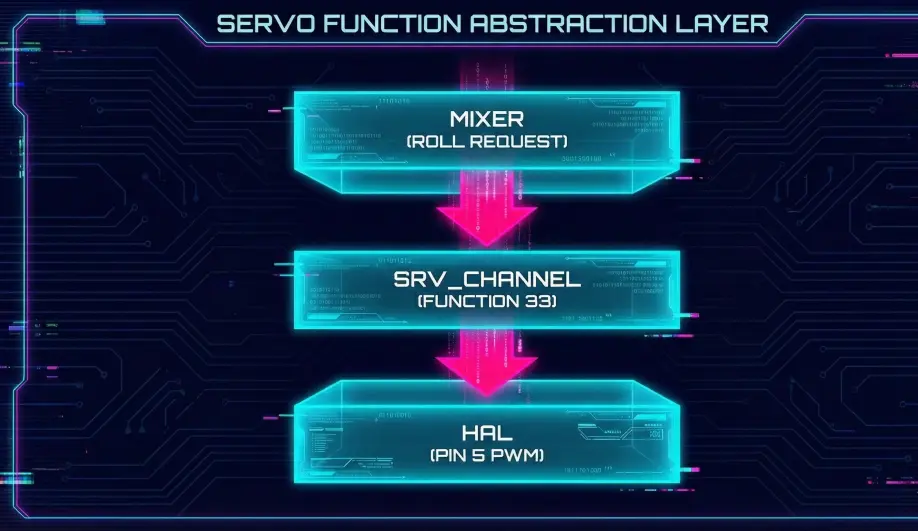

In ArduPilot, "Motor 1" is not physically tied to "Pin 1". Instead, there is a layer of abstraction called SRV_Channels. The Motor Mixer outputs to a logical "Function" (k_motor1), and you map that Function to any physical pin (SERVO5_FUNCTION) using parameters.

Theory & Concepts

1. Hardware Abstraction Layers (HAL)

A Hardware Abstraction Layer is a software bridge between the generic "Autopilot Brain" and the specific "Physical Pins" of a chip.

- The Logic: ArduCopter doesn't know what an STM32 or an H7 chip is. It just knows "Motor 1".

- The Bridge:

SRV_Channelsacts as the dispatcher. This allows the same ArduCopter firmware to run on hundreds of different boards with different pinouts.

2. Functional Mapping vs. Pin Mapping

- Legacy Systems: You had to plug Motor 1 into Pin 1. If Pin 1 broke, the board was useless.

- ArduPilot: Every pin is universal. If Pin 1 is dead, you can move the wire to Pin 8 and set

SERVO8_FUNCTION = 33. The "Brain" never needs to know the hardware changed.

Architecture (The Engineer's View)

1. The Function Enum

ArduPilot defines a list of ~150 possible output functions in Aux_servo_function_t.

- 33: Motor 1

- 34: Motor 2

- 35: Motor 3

- 36: Motor 4

- ...

- 1: Manual (Passthrough)

2. The Conversion Pipeline (calc_pwm)

When the Mixer says "Motor 1 at 50%", here is what happens:

- Normalization: The mixer outputs a float

0.5. - Scaling:

SRV_Channel::calc_pwm()takes this float. - Endpoint Lookup: It looks up the

SERVOx_MINandSERVOx_MAXparameters for the assigned pin. - Math:

PWM = MIN + (Scaled_Value * (MAX - MIN))- Example:

1000 + (0.5 * (2000 - 1000)) = 1500us.

- Example:

- Trim: If the function uses trim (like a servo surface), it centers around

SERVOx_TRIM.

3. Safety Interlocks

The SRV_Channels library also handles the Safety Switch.

- If the Safety Switch is active,

SRV_Channelsforces the output to0(ordisarmed_pwm), regardless of what the Mixer requests.

Debugging Tips

- "My Motor 1 is on Pin 5": This is valid. Set

SERVO5_FUNCTION = 33(Motor 1). - "My Servo moves backwards": Set

SERVOx_REVERSED = 1. This flips the math logic (1.0 input becomes MIN pwm).

Source Code Reference

- Conversion Logic:

SRV_Channel::calc_pwm() - Function List:

SRV_Channel.h

Practical Guide: Configuring a Gripper (Servo)

Let's say you have a 4-motor quadcopter (Channels 1-4) and you plug a Servo Gripper into Pin 5. You want to control it with Channel 9 on your transmitter.

Step 1: Physical Connection

- Plug the Servo Signal wire into Pin 5 (MAIN OUT 5).

- Warning: Most Autopilots do NOT provide 5V power on the servo rail. You must use a separate BEC to power the servo's Red/Black wires.

Step 2: Function Mapping

Tell ArduPilot what Pin 5 is.

- Parameter:

SERVO5_FUNCTION - Value: 59 (

RCIN9). - Meaning: "Whatever PWM value comes in from Radio Channel 9, send it directly to Output Pin 5."

Step 3: Endpoints

Servos burn out if you drive them too far.

- Open the Gripper: Toggle your switch. If it buzzes, reduce

SERVO5_MAX(e.g., from 1900 to 1800). - Close the Gripper: Toggle switch back. If it buzzes, increase

SERVO5_MIN(e.g., from 1100 to 1200).

Step 4: Reversing

If the switch is backwards (Up = Closed, Down = Open):

- Parameter:

SERVO5_REVERSED - Value: 1.