Multicopter Frame Mechanics

CRITICAL The frame is not just a skeleton; it is a mechanical component of the control loop. If the frame flexes, the PID loop fails.

1. Geometry & Mixing: The Deadcat Problem

1.1 True X

- Geometry: Motors are equidistant from the center. Symmetrical.

- Physics: Pitch and Roll authority are identical.

- Verdict: The perfect geometry for control theory. Used for Racing.

1.2 Deadcat (DC)

- The Design: Front arms are swept back/out to keep props out of the camera view.

- The Problem: The Center of Thrust is no longer aligned with the Center of Mass.

- The Consequence:

- Coupling: A pure Pitch command also creates a Yaw moment. A pure Roll command creates unequal motor loading.

- Motor Saturation: In a hard yaw spin, two diagonal motors may hit 100% throttle while the others are at 10%. The drone runs out of overhead ("authority") and drifts.

- The Fix: ArduPilot's

AP_MotorsMatrix.- You must select the correct frame type. ArduPilot calculates a custom Mixing Matrix that adjusts the motor output factors to account for the asymmetry.

- Note: You must run AutoTune. The PID gains for Pitch and Roll will be significantly different on a Deadcat frame.

2. Material Science: Stiffness vs. Resonance

Carbon Fiber is conductive, stiff, and light. But not all carbon is equal.

2.1 Stiffness (Modulus)

- Toray T700: High modulus (Stiff).

- The Physics: We want the frame to be infinitely stiff.

- Why? If the arm flexes, it acts as a "spring." When the motor accelerates, the arm bends back, then snaps forward.

- Phase Lag: This bending creates a time delay between the motor command and the vehicle movement.

- Tuning: Phase Lag limits your P-Gains. If you try to tune a flexible frame tightly, it will oscillate because the FC is reacting to delayed motion.

2.2 Resonance Frequency

Every object has a "Resonant Frequency"—the note it hums when you flick it.

- The Source: Motors vibrate at the frequency of their rotation (e.g., 150Hz to 400Hz).

- The Danger Zone: If your frame's resonant frequency overlaps with your motor RPM frequency, the vibration amplifies 10x.

- Result: The Gyro gets swamped with noise.

- The Solution: Stiffer frames (thicker arms, 5mm-6mm) push the resonant frequency UP (e.g., to 600Hz), moving it safely away from the primary motor frequencies.

3. Vibration Management

3.1 Soft Mounting (The Stack)

Since we can't eliminate all vibration, we must isolate the Brain.

- Gummies: Silicone grommets act as a mechanical Low-Pass Filter.

- The Tuning Trap:

- Too Hard: Vibration gets through -> Hot Motors.

- Too Soft: The stack "wobbles" during flips. The Gyro sees this wobble as vehicle movement.

- Symptom: "Bounce back" at the end of a flip. The FC fights the momentum of its own mounting gummies.

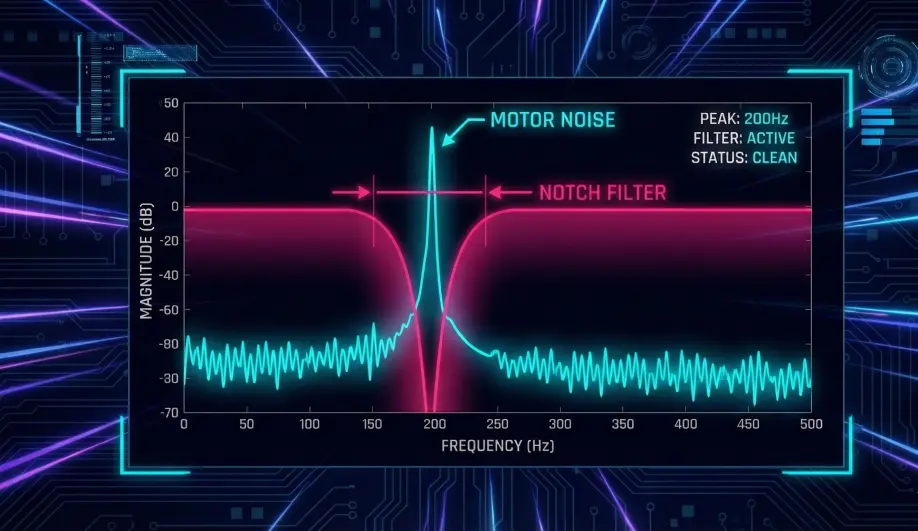

3.2 Notch Filtering: The Software Solution

ArduPilot's Harmonic Notch Filter is the magic bullet.

- How it works: It uses the RPM telemetry from the ESCs to determine exactly what frequency the motors are vibrating at in real-time.

- The Action: It places a digital "Notch" filter at that frequency on the Gyro data.

- The Benefit: It deletes the noise without adding the Phase Lag of a traditional Low-Pass filter.

- Result: You can fly a bent, noisy, resonant frame and it will still feel smooth, because the FC is blind to the vibration.